Key Features and Benefits of Aluminium Roofs

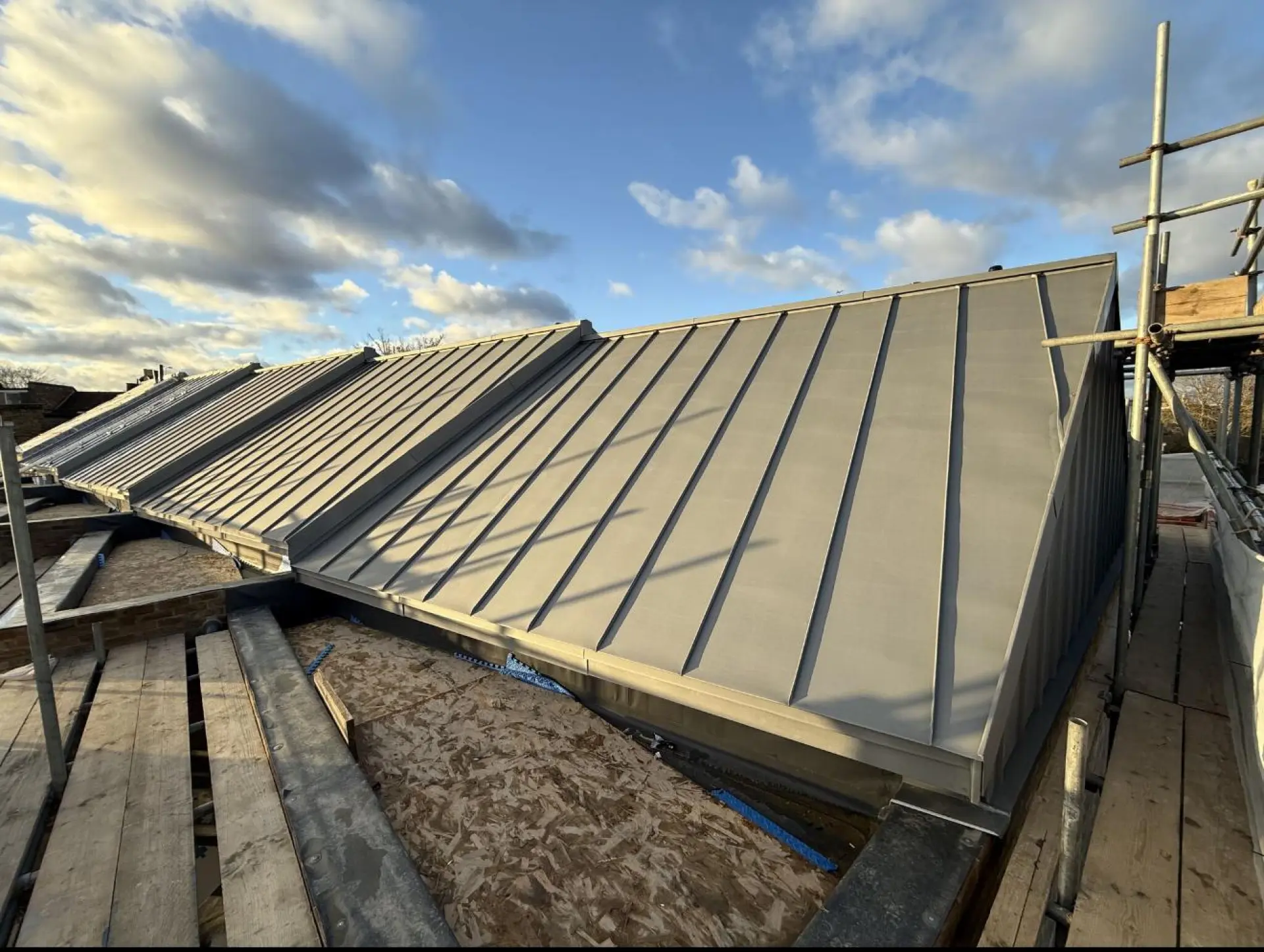

Aluminium roofing offers a smart balance of strength, lightness, and long-term value. Naturally corrosion-resistant, it forms a protective oxide layer that resists rust and coastal salt. High reflectivity helps reduce summer heat gain, while modern coatings provide colour stability and additional protection. Panels and standing-seam systems interlock tightly, supporting excellent wind uplift performance and shedding heavy rain quickly.

Aluminium is flexible, workable, and available in long lengths, so it suits complex roof geometries, low pitches, and curved profiles. It is non-combustible, compatible with solar mounting hardware, and recyclable at end of life with significant scrap value. Compared to heavier materials, aluminium lowers structural loads, often enabling faster installation and reduced disruption on refurbishment projects. Optional acoustic layers reduce rain noise.

Durability and Weather Resistance

Aluminium’s durability stems from both its metallurgy and the way modern roof systems are detailed. The metal rapidly develops a thin oxide film that self-heals when scratched, protecting against general corrosion without requiring brittle galvanic layers. In marine or industrial atmospheres where plain steel can pit or rust, architectural-grade aluminium performs strongly, especially when paired with high-build paint finishes or anodising.

Under weather extremes, standing-seam aluminium provides excellent wind resistance because continuous clips allow controlled movement while maintaining clamp force on the seams. Long panels shed rain quickly and are less prone to capillary ingress than lapped sheet products. Snow guards and concealed fixings can be integrated without piercing the weathering layer. With appropriate insulation and vapour control, condensation risk is well managed across cold and warm roof build-ups.

Compared with concrete or clay tiles, aluminium imposes far lower dead loads, so storm fatigue on fixings and battens is reduced. Unlike bituminous membranes, it does not soften in heat or become brittle in prolonged ultraviolet exposure. Versus fibre-cement, it offers far higher impact resistance and is non-friable. Fire performance is strong: aluminium is non-combustible and compatible with Class A or BROOF(t4) roof systems when detailed correctly.

Finally, modern coatings deliver colourfastness and chalk resistance, maintaining an attractive appearance even after decades of sun, rain, frost, and salt. Hail resilience is good for typical UK events, and surface denting is cosmetic. Thermal expansion is accommodated by sliding clips, slotted fixings, and sealant, preventing oil-canning issues and preserving watertightness through temperature cycles.

Weight and Ease of Installation

One of aluminium’s standout advantages is weight. At roughly one-third the density of steel and far lighter than tiles or slate, aluminium imposes minimal dead load on the structure. That can enable slimmer supporting members, ease over-roofing of existing buildings, and reduce cranage needs. Long, factory-formed standing-seam panels or interlocking shingles arrive ready to place, with consistent geometry that speeds setting-out. Crews can carry more area per lift, fixings are typically concealed, and weathering can be achieved quickly even on complex forms.

Accessories such as eaves closures, snow guards, rooflights, and solar brackets integrate cleanly. For refurbishments, the combination of lightness and dry installation often shortens programmes and minimises disruption to occupants and operations. Offsite fabrication further improves dimensional accuracy.

Maintenance and Lifespan Comparison

Compared with other roofing materials, aluminium generally requires less routine attention and offers a long service life. Its self-protecting oxide layer and durable factory finishes resist corrosion and colour fade, so maintenance is usually limited to periodic cleaning, inspection of fixings and flashings, and clearing gutters and debris traps. When coatings eventually age, over-painting is straightforward without replacing the substrate.

Steel roofs are tough but can demand closer coating surveillance, especially near coasts or pollution sources; if paint systems are compromised, red rust may develop and repairs become more urgent. Bituminous membranes are waterproof but can suffer from UV ageing, softening in heat, and brittleness in cold, leading to more frequent patching or overlay cycles. Concrete and clay tiles are robust yet heavy; fixings, battens, and underlays bear the brunt, and individual tiles may crack, slip, or delaminate. Fibre-cement offers modest maintenance but is more brittle under impact and can weather unevenly.

In lifespan terms, quality aluminium systems routinely achieve 40–60 years, and well-detailed standing-seam roofs can exceed that in benign climates.

Galvanised or coated steel commonly delivers 25–40 years depending on specification and exposure, with coastal sites at the lower end. Modern multi-layer bitumen roofs often target 20–30 years before significant refurbishment. Concrete and clay tile coverings may last 50 years or more, yet ancillary components and underlays can dictate earlier interventions.

Across all options, good detailing, compatible materials, controlled penetrations, and consistent maintenance consistently influence outcomes; aluminium’s combination of lightness, corrosion resistance, and repairability is a strong advantage.

Cost and Long-Term Value

One of aluminium’s standout advantages is weight. At roughly one-third the density of steel and far lighter than tiles or slate, aluminium imposes minimal dead load on the structure. That can enable slimmer supporting members, ease over-roofing of existing buildings, and reduce cranage needs. Long, factory-formed standing-seam panels or interlocking shingles arrive ready to place, with consistent geometry that speeds setting-out. Crews can carry more area per lift, fixings are typically concealed, and weathering can be achieved quickly even on complex forms.

Accessories such as eaves closures, snow guards, roof-lights, and solar brackets integrate cleanly. For refurbishments, the combination of lightness and dry installation often shortens programmes and minimises disruption to occupants and operations. Offsite fabrication further improves dimensional accuracy.

We provide installations, repairs, and custom detailing for residential and commercial properties. Our team offers clear advice, reliable workmanship, and long-lasting results. Contact us today to arrange a consultation or request a detailed quotation.